Eco Design Directive And Energy Efficiency

For expertly carried out FATs, call 01634 729 690.

Eco Design Directive And Energy Efficiency: A Focus Beyond Thermal And Wet Efficiency

The Eco Design Directive 1253/2014 marks a significant advancement in the European Union’s and the UK’s commitment to improving the environmental performance of energy-related products. As a leading manufacturer of air handling units (AHUs), we at ECE UK Ltd recognise that the directive places energy efficiency at the heart of modern HVAC system design. This focus shapes our approach to HVAC design standards, driving us to deliver AHUs that not only meet strict regulatory requirements but also support building energy performance, reduce carbon footprints, and achieve long-term sustainability goals for HVAC systems. It highlights the importance of considering overall energy consumption beyond traditional metrics, including thermal and wet efficiency.

The Importance Of Energy Efficiency In HVAC Design

Energy efficiency in HVAC systems refers to the ability of a system to deliver its intended function, whether heating, cooling, ventilation, or moisture control, while consuming the least possible energy. The primary aim of the Eco Design Directive 1253/2014 is to reduce energy consumption, minimise greenhouse gas emissions, and align with the UK’s climate goals and energy policy. By prioritising energy efficiency, the directive drives manufacturers like ECE UK Ltd to innovate and refine our air handling units (AHUs), enhancing HVAC energy performance while reducing energy use across the lifecycle of each unit.

Prioritising energy efficiency in HVAC systems brings multiple important benefits, including:

- Reducing environmental impact: By emphasising energy efficiency in HVAC systems, the Eco Design Directive helps lower the carbon footprint of air handling units (AHUs), contributing to a more sustainable built environment and supporting the UK’s efforts in combating climate change.

- Cost savings for consumers: Improved energy efficiency translates into reduced operational costs for building owners and occupiers. Compliance with the directive ensures that our AHU designs deliver significant energy savings, resulting in lower energy bills for end-users without compromising indoor air quality or comfort.

- Driving innovation and competitiveness: The focus on HVAC energy efficiency fuels continuous research and development. At ECE UK Ltd, it drives us to adopt new technologies, refine HVAC system design, and integrate advanced HVAC control systems, thereby enhancing both performance and market competitiveness in a fast-evolving sector.

This emphasis shifts our focus beyond narrow measures of efficiency to a holistic view of sustainable performance.

Understanding Efficiency Types In AHUs

To fully appreciate the intent and impact of the Ecodesign Directive 1253/2014, it is essential to recognise the different types of efficiency that influence HVAC system design and performance. While thermal efficiency has traditionally been a primary benchmark, the directive calls for a broader evaluation, prioritising the overall energy performance of air handling units (AHUs), including aspects such as fan power, control strategies, and heat recovery.

1. Thermal Efficiency – Dry And Wet

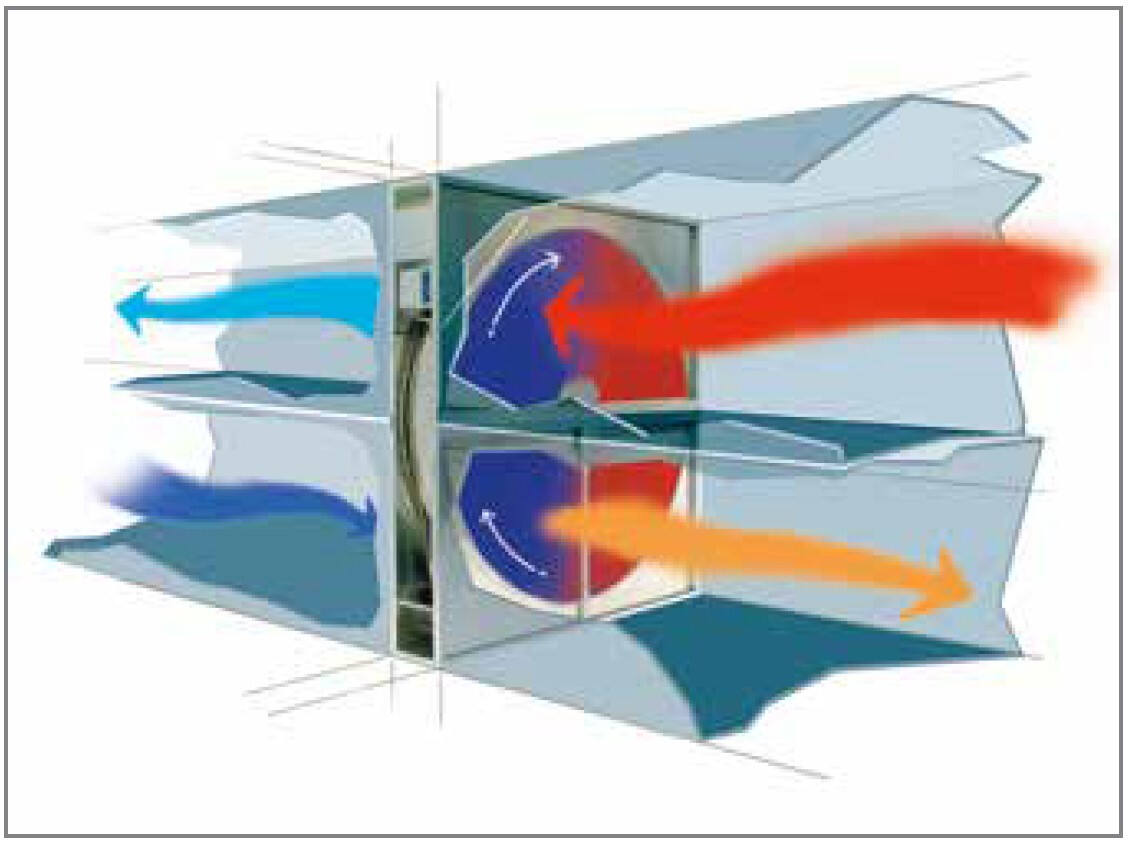

Thermal efficiency in AHUs refers specifically to the performance of the heat recovery system—how effectively heat is transferred from the exhaust (return) air to the incoming fresh (supply) air.

Dry Thermal Efficiency is measured under conditions where no condensation occurs. Only sensible heat is transferred, meaning temperature is exchanged without any change in moisture content. This is typical in mild or dry climate conditions.

Wet Thermal Efficiency is measured when condensation occurs on the heat exchanger surfaces. In this case, latent heat is recovered as moisture in the exhaust air condenses, releasing additional energy. This results in higher overall efficiency, especially in cold or humid climates.

These measures are crucial for evaluating heat exchanger performance under real operating conditions and are typically defined in accordance with BS EN 308.

Why thermal efficiency alone isn’t enough:

Optimising energy performance isn’t just about heat recovery (thermal efficiency), but also about system integration, control strategies, and appropriate sizing.

- System design flaws: Oversized AHUs—especially those not tailored to the building—may cycle frequently, leading to energy waste and reduced component lifespan.

This shows that sizing and selection, not just recovery efficiency, critically affect lifecycle efficiency—something the directive accounts for.

- Inadequate Control Systems: Ineffective sensor strategies can undermine performance. For example, VOC sensors are not reliable indicators of occupancy for demand-controlled ventilation. Instead, NDIR CO₂ sensors should be used for more accurate, occupancy-based airflow modulation.

Replacing VOC with CO₂ sensors for demand-controlled ventilation (DCV) aligns the system with occupancy-based modulation, reducing ventilation when spaces are unoccupied, which is exactly the type of intelligent efficiency Ecodesign seeks.

2. Wet Efficiency Vs Humidity Control

It’s important to note that wet thermal efficiency does not indicate the system’s ability to control humidity in the supply air. It simply reflects additional heat recovery due to moisture condensation in the return airstream. Active humidity management requires dedicated dehumidification or humidification systems, not just a high wet efficiency rating.

3. Energy Efficiency — The Broader Metric

The Eco-design Directive elevates energy efficiency in HVAC systems as the primary compliance target. Unlike thermal performances and Thermal efficiency (ERP), energy efficiency encompasses the total system energy use, evaluating the full operation from heat transfer to moisture management and controls.

This comprehensive perspective aligns with HVAC sustainability goals, targets carbon footprint reduction, and ensures compliance with building energy performance standards.

To illustrate the interrelationship and influence of these different forms of efficiency on AHU design, Table 1 below presents a side-by-side comparison of energy, wet, and thermal efficiency, including their focus, metrics, and impact areas.

Table 1: Overview Of Energy, Wet, And Thermal Efficiency In HVAC Design

| Aspect | Energy Efficiency | Thermal Efficiency – Dry | Thermal Efficiency – Wet |

| Focus | Overall energy use and system efficiency | Sensible heat recovery without condensation | Total heat recovery (sensible + latent) with condensation |

| What It Measures | How efficiently the AHU uses electrical energy for fans, coils, etc. | Temperature transfer efficiency under dry conditions (no moisture condensation) | Heat recovery performance when condensation occurs on exhaust side (latent + sensible) |

| Typical Applications | General HVAC systems, whole-building performance modelling | Mild climates, dry zones, summer operation | Cold or humid climates, winter operation, moisture-laden return air |

| Key Metrics | Specific Fan Power (SFP), kWh/year, COP of heating/cooling plant | % temperature efficiency (per BS EN 308 under dry conditions) | % total efficiency including latent recovery (per BS EN 308, ‘wet test’) |

| Relationship To Other Factors | Affected by controls, sizing, and component quality | Depends on heat exchanger surface area, air volume flow rates, bypass/damper function | Influenced by humidity of exhaust air, exchanger material, and temperature differentials |

| Overall Goal | Minimise total energy consumption while ensuring system performance | Recover as much sensible heat as possible to reduce heating/cooling demand | Maximise total heat recovery, especially in humid/cold conditions |

Integrating Energy Efficiency In Design Practices

At ECE UK Ltd, aligning with the standards of the Eco-design Directive 1253/2014 means embedding energy efficiency principles across every phase of our air handling unit (AHU) design and development process. This ensures our systems not only meet regulatory requirements but also exceed expectations for HVAC performance, sustainability, and indoor air quality (IAQ). Our approach includes:

1. Customised Configurations

Each AHU layout is tailored to the specific ventilation and operational requirements of the building. Unlike off-the-shelf systems, our custom solutions eliminate inefficiencies and optimise energy usage based on real-world demand and occupancy.

2. Precise Component Selection

We select fans, coils, and other internal components that precisely match the calculated thermal and ventilation loads. By avoiding over sizing or under sizing, we prevent unnecessary energy consumption and ensure long-term operational efficiency.

3. Adopting Advanced Technologies

ECE UK Ltd integrates cutting-edge components, including IE6-rated variable speed drives and high-efficiency energy recovery systems. These technologies play a key role in reducing HVAC system energy consumption and enhancing overall system performance.

4. Employing Intelligent Monitoring And Controls

Our AHUs feature Inteligent Energy Control systems that respond dynamically to real-time changes in occupancy and environmental conditions. This enables efficient airflow management and minimises waste through automated, demand-driven operation. Additionally, our asset information system provides real-time control and analytics, enabling better energy management and compliance with Eco-design standards.

5. Conducting Comprehensive Lifecycle Assessments

We evaluate the energy performance of our products throughout their lifecycle, from design and material sourcing to installation, operation, and end-of-life disposal. This cradle-to-grave approach ensures we deliver systems that align with long-term HVAC sustainability goals.

By applying this integrated design philosophy, ECE UK Ltd ensures that every air handling unit supports carbon footprint reduction, delivers measurable energy savings, and meets the evolving expectations of the UK’s built environment. Additionally, regular maintenance of the air handling unit plays a crucial role in maintaining long-term system efficiency, ensuring ongoing performance and compliance with energy-focused design objectives.

Conclusion

At ECE UK Ltd, we view the Eco-design Directive 1253/2014 as a crucial driver for enhancing energy efficiency in HVAC systems. By placing energy performance at the heart of our air handling unit (AHU) design strategy, we not only meet stringent environmental compliance standards but also deliver meaningful value to our clients through energy savings, operational reliability, and reduced carbon footprints.

While thermal performance dry and wet efficiency remain important technical factors, they represent only part of the wider effort to improve overall energy performance and ensure HVAC sustainability.

As we continue to innovate and refine our AHU solutions, our unwavering focus on energy efficiency will remain central to helping the UK achieve its climate goals, enhancing indoor air quality (IAQ), and setting new benchmarks for HVAC system design.

Contact our team today

Get straight through to one of our engineers and start discussing the needs of your new air handling unit. Our team are on hand to work out a custom solution for you and your project. Just call 01634 729 690 or send us an email at sales@eceuk.com to get started.