Advancing the NHS Net Zero Building Standards

For expertly carried out FATs, call 01634 729 690.

Advancing the NHS Net Zero Building Standards: A Focus on Life Cycle and Specific Fan Power with ECE UK Ltd

As the NHS advances towards its ambitious Net Zero Building Standard, energy efficiency in HVAC systems is a key priority. Central to this mission is ensuring that air handling units (AHUs) achieve Specific Fan Powers (SFP) of 1.3 kW/(m³/s) or lower, alongside a minimum heat recovery thermal-efficiency of 80%. At ECE UK Ltd, we recognise that these technical requirements not only support compliance but also contribute to the broader goal of a sustainable, low-carbon healthcare sector. It is equally vital for AHU manufacturers to adopt a whole-life-cycle approach, ensuring long-term efficiency and environmental responsibility. In this guide, we will explore how SFP, heat recovery, and life cycle design contribute to meeting NHS Net Zero goals and how ECE UK Ltd is helping to deliver this vision.

NHS Net Zero Building Standard Requirements

To achieve the NHS Net Zero Building Standard, air handling units in healthcare buildings must meet specific and measurable targets that reduce both operational and embodied carbon. These include:

- Specific Fan Power (SFP): AHUs must achieve an SFP of ≤ 1.3 kW/(m³/s), enhancing ventilation efficiency while cutting energy use.

- Heat recovery efficiency: A minimum of 80% heat recovery is required, reducing wasted energy and lowering operational costs.

- Life cycle responsibility: Designs must consider whole life cycle costs, energy use, maintenance, and recyclability, ensuring long-term value and sustainability.

- Embodied carbon focus: Design teams must assess embodied carbon using tools such as the CIBSE Embodied Carbon Calculator, which supports smarter material choices and sustainable construction practices.

- Integration of low-carbon systems: A blend of passive design and energy-efficient technologies is required to meet Building Sustainability Performance Targets.

ECE UK Ltd’s integrated management systems and engineering expertise ensure our solutions align with these exacting standards.

Optimising Specific Fan Power (SFP) for Net Zero Healthcare

Understanding Specific Fan Power and Its Importance

Specific Fan Power (SFP) measures the energy consumed by fans in relation to the airflow they produce. Under the NHS Net Zero Building Standard, achieving an SFP of ≤ 1.3 kW/(m³/s) is not merely a box-ticking exercise; it requires careful design and engineering to balance performance, efficiency, and sustainability in healthcare buildings. This target helps reduce operational carbon emissions and aligns with broader low-carbon building systems and green building initiatives in healthcare.

At ECE UK Ltd, we recognise that meeting this standard requires a detailed understanding of both the internal resistance within the air handling unit (AHU) and the external resistance introduced by the building’s ductwork. When done right, this not only ensures compliance but also contributes to the NHS’s long-term energy and carbon reduction goals.

The Role of Duct Design: Length and Velocity

The design of ductwork is critical in helping healthcare facilities meet SFP targets. Even small adjustments can have a significant impact on ventilation performance, indoor air quality, and the overall efficiency of HVAC systems in healthcare facilities.

1. Reducing Duct Length

One of the most effective strategies for achieving the NHS SFP requirement is minimising duct length. Longer ducts increase friction and pressure losses, forcing fans to work harder and consume more energy. By designing ductwork that is as short and direct as possible, we can:

- Lower external pressure losses

- Improve overall system efficiency

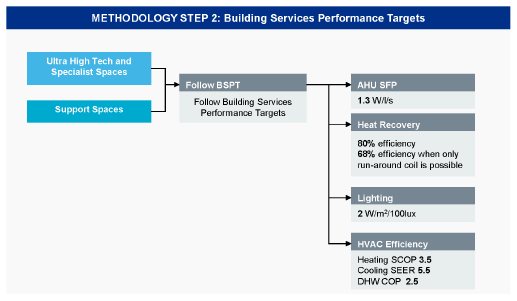

- Help meet Building Services Performance Targets (refer to the key targets in Figure 1)

2. Maintaining Low Air Velocity

Air velocity within ducts is another critical factor. Higher air velocities create turbulence and friction, which not only raise energy consumption but can also affect indoor air quality in hospitals. Our team at ECE UK Ltd supports designing low-resistance ducting systems that:

- Operate at lower velocities

- Reduce energy requirements

- Enhance comfort for patients and staff

Figure 1: NHS Net Zero Building Standards

– Key Building Services Performance Targets (BSPTs).

Integrating High-Efficiency Air Handling Units

Achieving the NHS Net Zero Building Standard requires more than meeting a single performance figure, and it means selecting air handling units (AHUs) that combine low Specific Fan Power (SFP) with outstanding heat recovery capabilities. At ECE UK Ltd, we champion the integration of advanced technologies that help our clients meet and exceed these requirements.

One key feature we recommend is the use of IE6 permanent magnet motors in AHUs, which deliver crucial benefits:

1. High Efficiency Across All Conditions

IE6 permanent magnet motors are designed to provide exceptional efficiency across a wide range of operating scenarios. This ensures that energy consumption is minimised, whether the system is running at full capacity or part load, a critical factor in complying with NHS standards and supporting long-term sustainability.

2. Smarter

Adaptive

Control

These motors work seamlessly with modern control systems that adjust fan speeds dynamically in response to real-time demand. By matching performance to actual ventilation needs, energy waste is reduced, helping to achieve the SFP target of 1.3 kW/(m³/s) without compromising comfort or air quality.

3. Enhanced Heat Recovery Integration

Selecting the right heat recovery system is essential to achieve the NHS’s minimum 80% heat recovery efficiency. We prioritise heat exchangers and integrated solutions that maximise energy capture and reuse, thereby reducing carbon emissions and operating costs throughout the building’s lifespan.

Designing for Sustainability: Life Cycle Considerations Beyond SFP

Beyond achieving the specific fan power and heat recovery targets, the NHS Net Zero Building Standard calls on AHU manufacturers to adopt a full life cycle perspective. At ECE UK Ltd, we champion a life cycle approach to air handling unit (AHU) design, ensuring that our solutions deliver environmental benefits throughout their entire lifespan, not just at the point of installation.

This holistic approach aligns with the NHS’s vision for healthcare estates that are not only energy-efficient but also responsible in terms of material use, carbon footprint, and end-of-life impact.

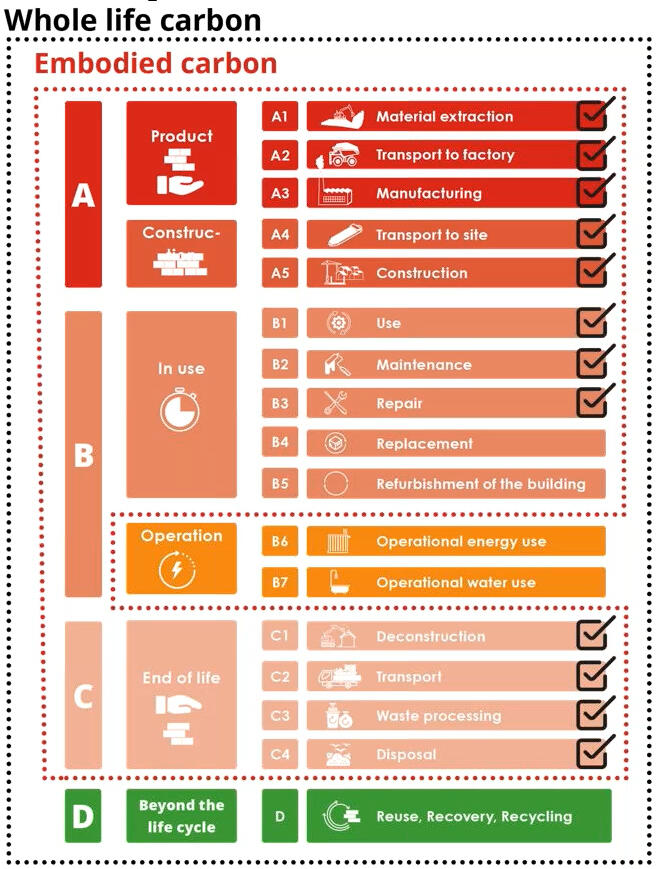

This encompasses a detailed analysis of carbon impacts across every stage of a product’s lifecycle, as illustrated in Figure 2.

Figure 2: Understanding Whole Life Carbon:

Breakdown of embodied and operational carbon stages throughout a building’s lifecycle.

Key elements of this life cycle focus include:

1. Sustainability in Materials

Selecting the right materials at the design stage can significantly reduce environmental impact. That’s why we prioritise durable, sustainable materials that:

- Require fewer replacements over time

- Minimise resource use during manufacturing

- Support embodied carbon reduction targets

By choosing materials responsibly, we help lower both the operational and embodied carbon of healthcare buildings.

2. Energy Use Across the Life Cycle

Sustainability isn’t just about how a system performs on day one — it’s about its total impact over time. At ECE UK Ltd, we evaluate the energy consumption of our AHUs at every stage:

- Manufacturing

- Delivery and installation

- Day-to-day operation

- Maintenance

- Decommissioning

This approach ensures that efficiency gains are not lost over the long term, supporting the NHS’s goal of achieving low-carbon building systems.

3. Recyclability and Circular Design

End-of-life planning is a vital part of life cycle sustainability. We design AHUs that are:

- Easy to disassemble

- Made from recyclable components

- Aligned with circular economy principles to reduce landfill waste

This helps healthcare organisations meet net-zero waste objectives and reinforces their environmental leadership.

Tools such as the CIBSE Embodied Carbon Calculator (see Figure 3) help quantify these impacts throughout a product’s lifecycle.

By embedding life cycle thinking into every product, ECE UK Ltd helps ensure that today’s air handling solutions support a sustainable future for NHS buildings.

Collaborative Approach to Achieving NHS Compliance

At ECE UK Ltd, we recognise that achieving the NHS Net Zero Building Standard is not the responsibility of a single party, and it demands a collaborative effort between engineers, HVAC professionals, and manufacturers. By working together from the earliest design stages, we can ensure that every element of the HVAC system is optimised for performance, life cycle efficiency, and sustainability. This integrated approach enables a holistic understanding of both internal AHU resistance and external duct resistance, allowing for innovative solutions that enhance energy efficiency, reduce carbon emissions, and support long-term compliance.

Conclusion

As the NHS forges ahead on its path to achieving net-zero emissions, understanding and optimising Specific Fan Power (SFP) in HVAC systems is essential. By implementing shorter, low-velocity ductwork designs and incorporating high-efficiency air handling units with IE6 permanent magnet motors, ECE UK Ltd is committed to helping healthcare facilities meet the SFP requirement of 1.3 kW/(m³/s) and achieve a minimum heat recovery efficiency of 80%.

Furthermore, by adopting a life cycle approach to AHU design, considering material sustainability, energy use, and recyclability, we can ensure long-term sustainability and environmental responsibility.

Through close collaboration with engineers, HVAC professionals, and manufacturers, we can create more efficient, sustainable healthcare environments that support the NHS Net Zero Building Standard and the broader goals of energy efficiency and carbon reduction. Together, we are shaping a healthier, greener future for all.

Discover how we apply this approach in our Hinckley CDC Case Study

Contact our team today

Get straight through to one of our engineers and start discussing the needs of your new air handling unit. Our team are on hand to work out a custom solution for you and your project. Just call 01634 729 690 or send us an email at sales@eceuk.com to get started.