Supply and extract unit 3-way mix

Call us on 01634 729 690

SEU3MX supply and extract unit 3-way mix

Air handling units that incorporate a 3-way mixing plenum are incredibly useful to save energy. The supply and extract unit is ideal for locations which are not designed for human occupancy as clarified under Eco Design Commission Regulation (EU) No 1253/2014, such as distribution centres, warehouses, pharmaceutical facilities, and data centres.

Your unit will deliver practical benefits including lower energy consumption, smaller environmental impact, and reduced need for investment in heat generation and distribution. It is a sophisticated piece of machinery that delivers genuine results for your site.

If the unit has a connection that leads outside the building with a supply or exhaust air flowrate in regular operation of minimum 10% of the total declared recirculated air flowrate, then it is considered a ventilation unit and falls under Regulation 1253/2014.

Review our Supply & Extract Unit 3-way Mix brochure here:

Contact us for a custom solution

Our design engineers are here to create a completely bespoke air handling unit for you. Just get in touch to reach one of our experts and get started. Call 01634 729 690 or send an email to sales@eceuk.com today and get started. If you already have a more detailed idea of your project, you can fill out our enquiry form to give us a comprehensive overview of your project.

Operation

It is common for the supply and extract air handlers to be joined together, either stacked on top of each other or installed side-by-side. This unit includes three sets of dampers, one for the fresh air, one for the exhaust air, and a mixing damper between the two air streams. The mix of fresh air and recirculated air can be finely adjusted to suit the needs of the building. Typically, as fresh air and exhaust air dampers are driven from 0% to 10% open, the mixing damper will in turn be driven from 100% open to 90% open to ensure a constant volume of supply and extract air.

Ancillary items

Your supply and extract unit comes with a number of extras so you can tailor it to meet the needs of your facility.

Filtration

Filtration is an essential part of any air handling unit. Our advanced filters will ensure the health and wellbeing of everyone at your site by removing particulate from the air.

Direct heating

Either electric air heater batteries or gas-fired, fuel-burning heaters are placed directly in the air stream to provide temperature control.

Indirect heating and cooling

Indirect heating and cooling coils are fed with hot water, chilled water or refrigerant gas to regulate the temperature of the air utilising central plant.

Humidification

Heating the air for extended periods can dry it out, creating an uncomfortable atmosphere and increasing static electricity in the air. Humidification reintroduces moisture to prevent this.

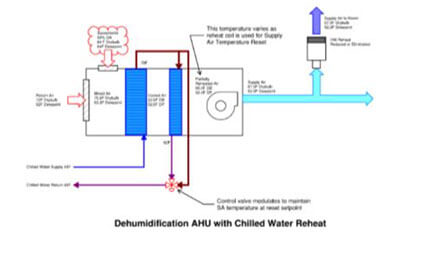

Dehumidification

The cooling coil can over-cool and at the same time increase moisture, by introducing a heating coil and warming the air we can reduce moisture and keep the room at the optimum temperature and relative humidity.

Intelligent energy controls

Our air handling units are available with intelligent energy controls as standard. These monitor the return air quality, energy recovery, and CO2 concentration. They are essential to maintaining optimal energy efficiency as well as your desired fresh air requirements. You’ll have a highly sophisticated level of control with an advanced tool that is flawlessly integrated into your existing building management system.

Net zero carbon

Reducing and offsetting carbon emissions is a major part of curbing climate change laid out in the 2016 Paris Agreement. Your new air handling unit is an excellent way to help your site achieve carbon neutrality as it delivers ventilation and fresh air with great efficiency, mitigating the effects of what is often an energy intense process.

Factory acceptance test

Our expert technicians will complete a full Factory Acceptance Test (FAT) on your AHU after its manufacture. This will verify that it has been built to the highest standard and will work according to the specification laid out.

- Completed FAT protocol

- Installation, Operation and Maintenance (IOM) manual

- Recommended spare parts lists

- Certificates of compliance

- As-built certified drawings

- Air tightness certificate

- Filter DOP certificate

Contact our experts

Our team is here to meet your air handling requirements. Get in touch with expert engineers by calling 01634 729 690 or send us an email at sales@eceuk.com.