AHU Systems integration

Call us on 01634 729 690

Our comprehensive AHU services

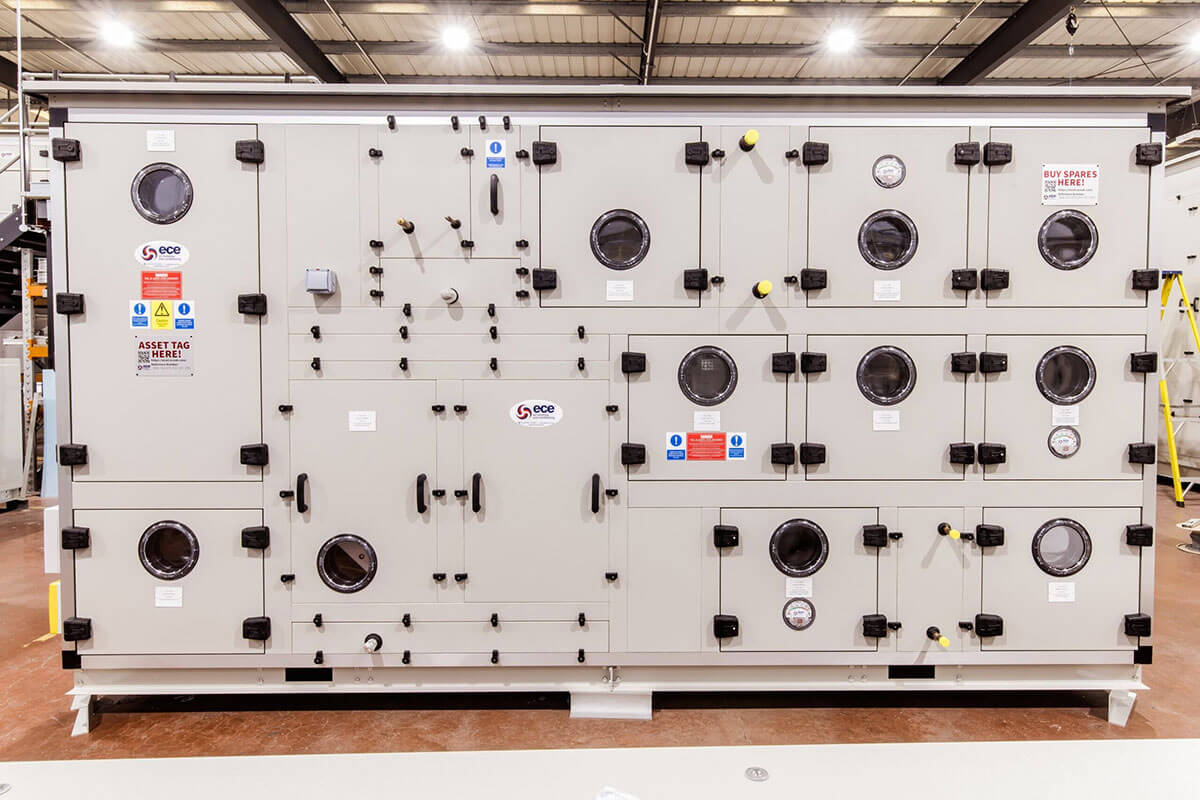

At ECE UK, we deliver custom solutions to your air handling needs. Our services cover the entire lifespan of your air handling unit. We can remove your old unit, design and install a new one, refurbish an existing unit, and more. Our team will communicate with you every step of the way, so you’ll always have an expert opinion at each stage of your project. With so much industry expertise in-house, our team provides a huge range of solutions to boost efficiency, sustainability, and wellbeing at your site. Our bespoke products can be customised down to the millimetre and are hand-built to meet the unique needs and requirements of your site.

Choose us for your new AHU

We can meet all your air handling needs, from planning to practical completion and beyond. Get in touch to find out more about our expert services. Just call 01634 729 690, email sales@eceuk.com, or fill out our contact form.

Comprehensive air handling services

In the last forty years we have grown in scope and prowess to encompass every stage of the air handling unit production process. From the earliest design stages right through to practical completion and aftercare, we have the in-house expertise you require.

Design and installation

Our design and installation process prioritises your needs. We use your site’s requirements to create a custom designed air handling unit that will meet your needs. Our team will deliver and install your AHU with precision and care.

1

Maintenance

Keep your air handling unit working at its best with scheduled maintenance. Our team use their years of experience in the industry and our extensive asset management systems to keep your AHU working optimally.

3

Refurbishment

If your air handling unit can be improved or isn’t running as it should, contact us for professional refurbishment services. We will refurbish and repair any AHU, even if it was manufactured and installed by another company.

5

Plant movement

As part of our commitment to offering a complete package for your air handling unit, we can take care of the plant movement involved in transporting and unloading your new AHU. You can rely on our team to handle the entire process.

2

Condition reports and testing

We complete highly accurate and detailed condition reports and testing to identify any problems or worn components. Our Technical Director will visit your site to assess the health and efficiency of your air handling unit.

4

Your custom air handling system

Our team delivers completely bespoke air handling solutions, prioritising your requirements at every stage of the process. Following your consultation with our design engineers, we will work diligently to craft a unique air handling unit that increases the energy efficiency of your site, enhances wellbeing, and improves air quality. We operate across a huge range of sectors and design AHUs to meet the logistical and legal requirements of the most complex sites.

Speak to the experts

Enquire today to get a quote for your bespoke air handling unit. Our team are always on hand to listen to your requirements and design the perfect solution. Call 01634 729 690 or email sales@eceuk.com to get started.

The journey to net zero carbon

Of a building’s greenhouse gas emissions, as much as half can be a result of heating, ventilation, and air conditioning. Having a system that provides the air that you need as efficiently as possible is vital to reducing your building’s carbon footprint and achieving the net zero carbon goals set out in the 2016 Paris Agreement. Our air handling units are not only built for efficient operating, but wherever possible integrate sophisticated energy recovery technology that recuperates hot or cool air as appropriate and repurposes it, or the energy from it. This is possible with out compromising the level of hygiene, ventilation, or filtration of the air at your site, making it a highly worthwhile investment.

Why choose us?

ECE UK has been designing, manufacturing, and installing bespoke air handling units since 1979. We are a well-established and highly experienced team that produces custom solutions to meet a huge range of requirements.

Knowledgeable

Our knowledge of both the technical elements of air handling units and the wider industry is unmatched. We hand build AHUs to your specifications, delivering a perfect solution every time, and have the expertise to improve air quality to a huge range of sites with complex needs and requirements.

Experienced

Over the last forty years, we have cultivated a team of industry experts. Some of our engineers have been with us for decades and their experience is invaluable. It enables them to craft specific solutions that deliver the results you need while accounting for the specific requirements of your sector.

Skilled

The skill and talent of our engineers ensures we have the right solution for any need, however complex. Whether it is an issue of space, access, or capacity, we have the answer. We continuously train our team and give them opportunities to advance their skills so you can be confident you’re working with the best.

Past projects

Our team have completed complex projects throughout the UK to an impeccable standard. We’ve worked with top contractors at prestigious institutions and have even exported our AHUs abroad. Take a look at our work and see for yourself the extraordinary results we’ve achieved.

Speak to the

specialists at ECE

Get in touch with our team for more information about your new custom air handling unit. Call 01634 729 690 or email sales@eceuk.com to get started today.