Air Handling Units

Call us on 01634 729 690

Our range of air

handling units

We offer a broad variety of different air handling that are customised to meet even the most complex project requirements. Every type of AHU we provide is uniquely designed by our engineers to deliver clean and conditioned air according to your site’s specifications. We have produced bespoke systems for contractors, consultants, and end users such as Imperial College London and the Savoy Hotel and provided highly advanced solutions to hospitals to ensure air is of the proper quality and cleanliness. You can be assured that your new AHU will be fully bespoke and hand-built to meet your site’s unique needs.

What sort of air handling unit do you need?

Get in touch with our dedicated experts. We put your needs at the forefront of our process, creating a custom unit that perfectly suits your site. You can discuss your requirements with our team by calling 01634 729 690, emailing sales@eceuk.com, or by filling out our contact form.

Our air handling units

At ECE UK, we design and build bespoke air handling units (AHUs) to transform your site’s air quality and comfort. Every system is engineered to your precise requirements, ensuring optimal performance and energy efficiency. Our expert team collaborates with you at every stage—from initial design and installation to aftercare—to deliver solutions trusted by end users across a wide range of sectors, including healthcare, education, and hospitality. With decades of experience and a commitment to excellence, we guarantee a custom AHU that meets the unique challenges of your commercial or industrial project, backed by industry-leading support and rigorous quality assurance.

Your custom air handling system

When you choose us for your air handling unit, you will receive a completely bespoke solution. There is no ‘one size fits all’ approach with us. Your AHU will be designed by our dedicated engineers to meet the practical needs of your site. This will deliver the desired volume of fresh, clean, and oxygenated air that is so critical to health and wellbeing while accounting for the complexities of your site. We provide our services to contractors and end users in a broad range of sectors and are well versed in the unique requirements and legal obligations of each. We are the team to choose for a personalised solution that will transform your site’s air quality.

Start designing your custom AHU

Get in touch with our engineers on 01634 729 690 or sales@eceuk.com and discuss your air handling requirements. You can also fill out our enquiry form to give us a detailed overview of your project’s needs.

Achieve net zero carbon with air handling units

Our custom-designed air handling units are an energy efficient way to ensure your site is receiving the temperature control and filtration it requires. Many of our units employ heat recuperators so that heat from the extract air is used to warm the supply air without compromising the quality or cleanliness. This reduces the amount of energy that must be spent heating the air and your overall consumption. Our products are designed to maximise energy efficiency both in their operation and by repurposing heat.

Eliminate sick building syndrome

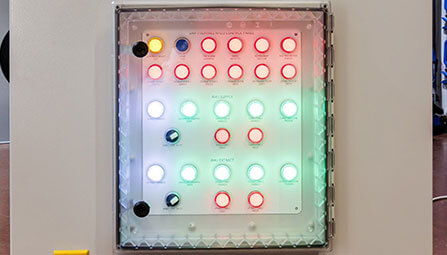

Sick building syndrome is when a building is causing health problems in the occupants. This can be due to materials, location, but is very often due to the indoor environment. Low-quality air, pollutants, and inadequate ventilation have a major impact on the health of a building and its occupants. Our units are designed to replenish the air at your site. They efficiently remove dirty air, recuperate heat to conserve energy, and delivers fresh air. With intelligent controls and fine levels of filtration available, you’ll be able to monitor and precisely adjust the air at your site and ensure it is at the exact quality you need.

Air handling unit factory acceptance test

Every unit we design, manufacture, and install can receive a Factory Acceptance Test (FAT). This is a process conducted after your AHU has been manufactured at our factory to verify that it will deliver the results it should. Our experienced engineers will check that it has been built in accordance with design specifications such as HTM03:01, VDI6022, and BS EN1886. They will also ensure that the components and construction match our certified drawing as well as a consultant’s design where relevant. This will also involve an electrical point to point test to ensure that the installation is safe. We will even provide training in how to change motors, filters, and properly remove the door guard so that engineers on your site can maintain the AHU after installation.

- Completed FAT protocol

- Installation, Operation, and Maintenance (IOM) manual

- Recommended spare parts lists

- Certificates of compliance

- As-built certified drawings

- Ait Tightness certificates

- Filter DOP certificate

Why choose ECE UK for your air handling unit?

We provide a level of product customisation and customer service that is unmatched in the industry. Our dedicated teams of in-house professionals provide everything you need during every stage of the process. You’ll receive a bespoke air handling unit, designed, installed, and maintained by experts.

Knowledgeable

Our team’s knowledge covers every part of the process. Our engineers will produce your custom design in accordance with your needs. They will collaborate closely with the rest of our team, so any additional services you need will be completed by engineers who are already experts on your AHU and your site.

Experienced

Started in 1979, ECE UK has been providing top-quality air handling units for over four decades and have become industry leaders. Many members of our team have been with us for more than a decade and are intimately familiar with every stage of the process.

Skilled

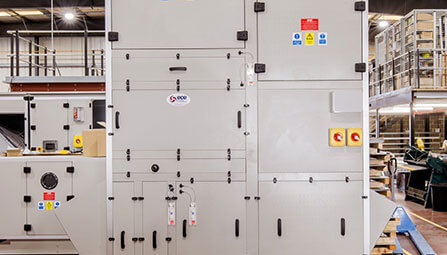

We use highly advanced technology in our factory, but we’ve found that no machine can replace the human touch. That’s why each of our air handling units are hand built by our expert technicians in our Kent facility. This is the best way to deliver a highly precise result that gets you the results you need.

Get your AHU from

the experts

You can reach our engineers today by calling 01634 729 690 or emailing sales@eceuk.com. You’ll immediately be in touch with a dedicated expert ready to begin working on your custom air handling unit.