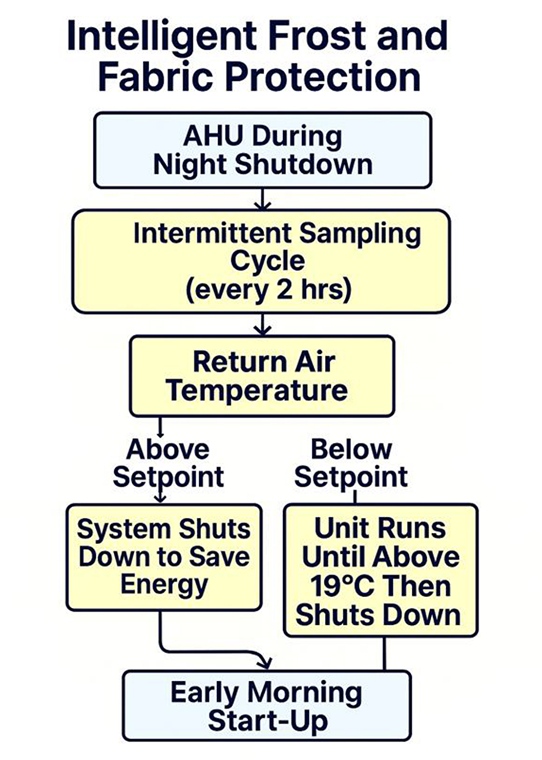

How ECE UK’s Intelligent System Works

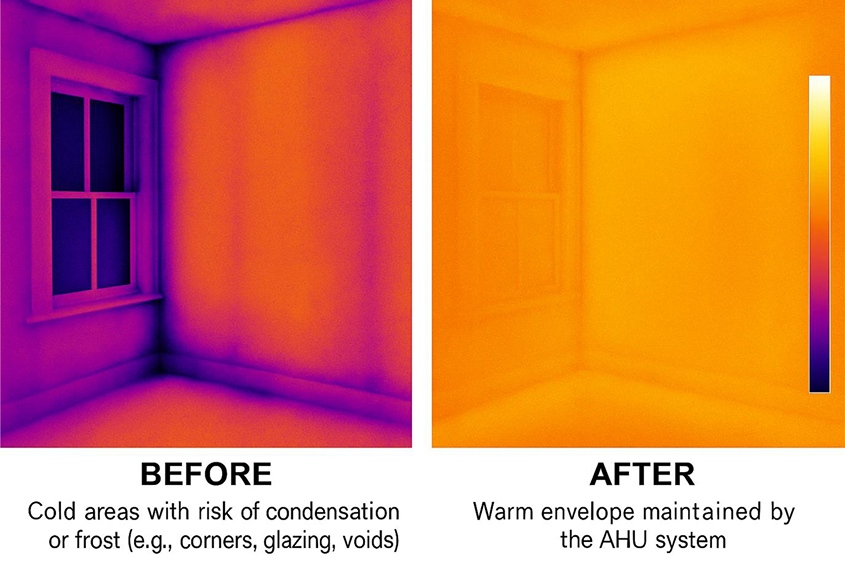

ECE UK’s Intelligent Energy Control system revolutionises traditional building protection through dynamic, energy-conscious control sequences that replace outdated static frost coil methods:

Advanced Control Features

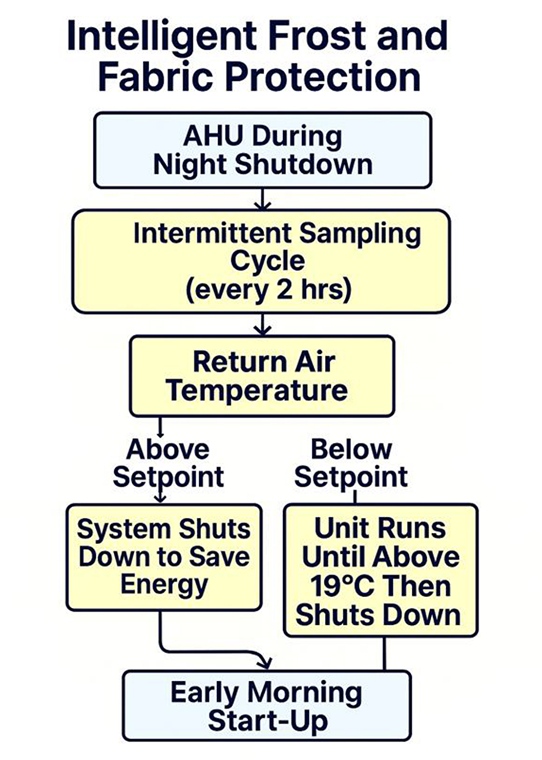

Scheduled Night-Time Monitoring: The air handling unit activates briefly every 2 hours (or user-defined intervals) during unoccupied periods, ensuring consistent monitoring without continuous energy consumption.

Precision Return Air Temperature Sampling: The return air temperature sensor operates the unit for approximately 10 minutes to assess internal conditions accurately, providing real-time data for informed decision-making.

Condition-Based Operation: When return air temperature exceeds the non-occupied temperature setpoint (typically 14-16°C), the unit automatically shuts down to conserve energy, demonstrating intelligent air handling unit control.

Adaptive Fabric Protection Activation: If temperatures fall below the predetermined setpoint, the system continues operating to gently reheat the space until safe thresholds are restored, ensuring continuous fabric integrity maintenance.

This sophisticated control logic operates directly through the Trend IQ4 controller, eliminating the need for dedicated BEMS or costly heating hardware like mechanical frost coils.