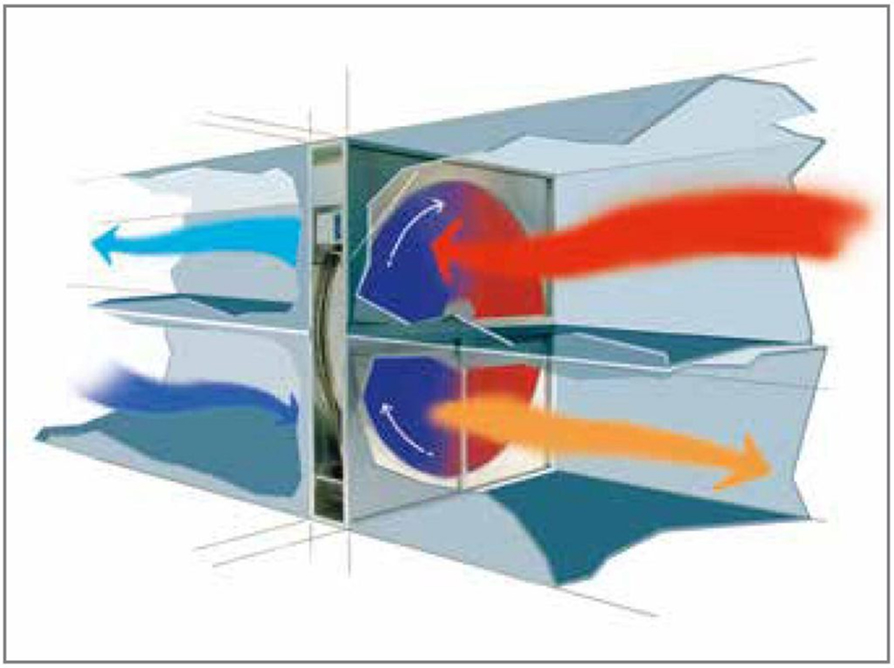

Thermal wheels, also known as rotary heat exchangers, are commonly used in HVAC systems for their high energy recovery ventilation performance. But their application in sensitive environments like operating theatres, isolation rooms, and clinical laboratories raises concerns due to strict air quality and infection control requirements.

Even though standards like HTM 03-01 may approve the use of thermal wheel heat recovery units in applications with filters designed to prevent microbiological contamination, there are important reasons why their use might still be discouraged or avoided in certain healthcare or sensitive environments.