AHU Filter Selection Guide | ISO 16890 & ODA/SUP Explained

For expertly carried out FATs, call 01634 729 690.

AHU filters selection guide: Selecting the correct filters for the job

Filter selection in Air Handling Units (AHUs) plays a critical role in meeting indoor air quality (IAQ) standards, maintaining occupant health, and ensuring energy-efficient operation. This section serves as your essential AHU filters selection guide, explaining how to choose single-stage or multi-stage filters based on real-world air pollution data from DEFRA, ODA/SUP classification under the EN ISO 16890 standard, and expected cumulative filtration efficiency (ePM1, ePM2.5, and ePM10 ratings).

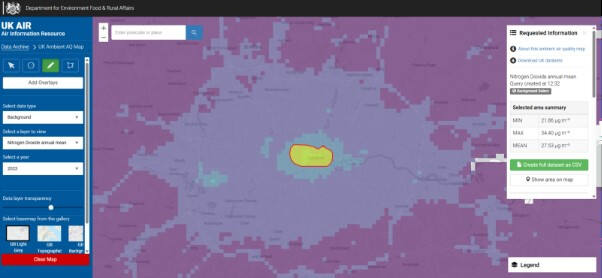

Understanding the Outdoor Air Quality (ODA Category) is the first step. You can find DEFRA air data, including annual mean PM2.5 air quality levels for the UK, from the following official and reliable sources: (As shown in figure 1)

Step 1: Determine outdoor air quality (ODA Category)

Begin by identifying the full site address, including the postcode where the air handling unit (AHU) is to be installed.

Refer to DEFRA’s latest annual mean PM2.5 data to determine the correct Outdoor Air (ODA) classification for the location:

- ≤10 µg/m³ → ODA 1 (Clean Air, Urban)

- 10–15 µg/m³ → ODA 2 (Moderate Pollution, Town or City)

- 15 µg/m³ → ODA 3 (Heavy Pollution, Industrial)

Assigning the correct ODA category ensures that the selected filtration system aligns with local air quality levels and complies with EN ISO 16890 standards.

Step 2: Define indoor air quality needs (SUP Category)

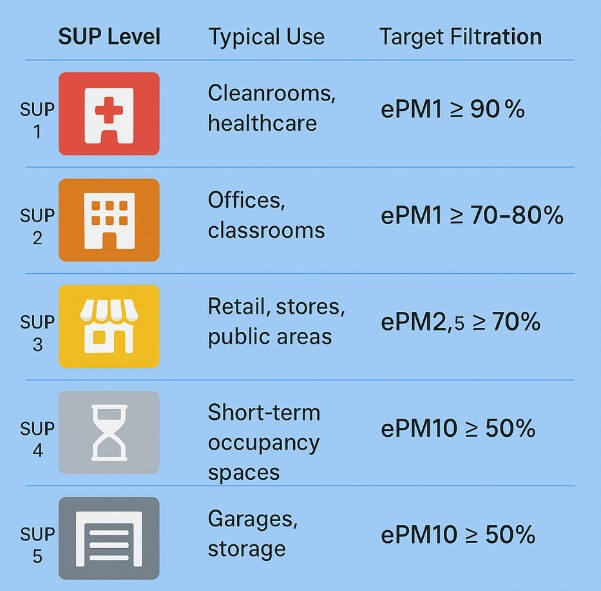

Based on the application type, assign the appropriate Supply Air (SUP) category, along with its corresponding target filtration efficiency.

(As shown in Figure 2)

Figure 2: Table demonstrating the SUP category and corresponding target filtration

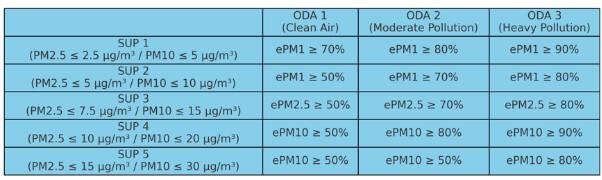

Figure 3: Air quality categorisation

The matrix is aligned with EN ISO 16890 and helps ensure compliance by defining the minimum cumulative ePM1 or ePM2.5 efficiency levels for your specific AHU configuration.

Step 3: Identify minimum filtration efficiency using the ODA/SUP matrix

Consult the ODA/SUP matrix (see below) to determine the minimum required cumulative filtration efficiency for your application based on the assigned Outdoor Air (ODA) and Supply Air (SUP) categories. (As shown in Figure 3)

For example: A healthcare project located in a high-pollution zone (ODA 3) with a SUP 2 requirement would typically demand a higher filtration class to remain compliant.

- ODA 3 + SUP 2 → ePM1 ≥ 80%

- ODA 2 + SUP 3 → 5 ≥ 70%

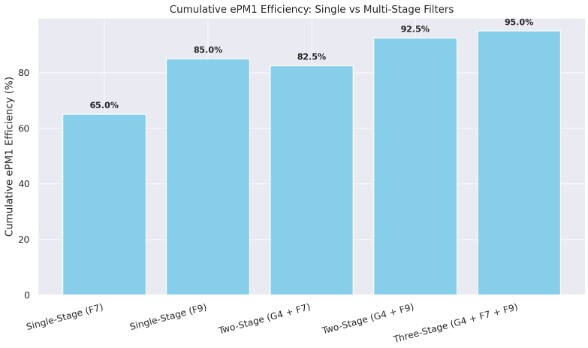

Step 4: Select single or multi-stage filters based on cumulative ePM1 efficiency

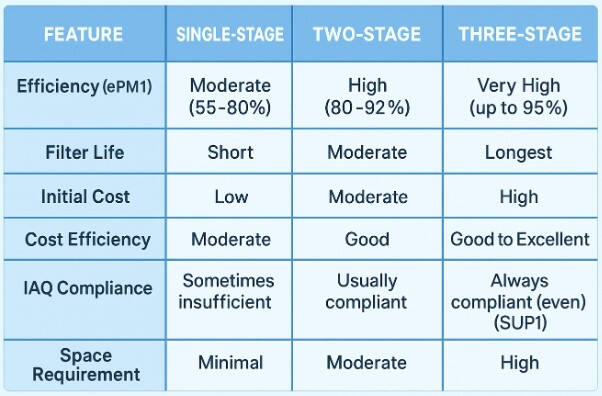

Refer to the cumulative ePM1 efficiency chart below (As shown in Figure 4). It compares the performance of:

- Single-stage filters (F7 or F9)

- Two-stage filters (e.g., G4 + F7, G4 + F9)

- 3-stage configurations (e.g., G4 + F7 + F9)

Use this to validate that your selected combination meets or exceeds the required filtration efficiency for the assigned ODA/SUP classification.

Figure 4: Comparison table for using Single, Two and Three Stage Filtration

Note: Cumulative ePM1 efficiency refers to the total filtration impact of all stages combined. For instance, a G4 + F9 setup may outperform an F9 alone due to better particulate loading and reduced leakage across stages. (As shown in Figure 5)

Figure 5: Cumulative ePM1 efficiency

To select single-stage or multi-stage filters using cumulative efficiency, the key is to match the final required EN ISO 16890 efficiency (ePMx) with your ODA/SUP combination.

To further simplify the procedure, use our tool to select the correct filters and confirm compliance with ISO EN 16890: ECE UK Filter Configuration Tool.

Cumulative Efficiency & ODA/SUP Compliance Tool

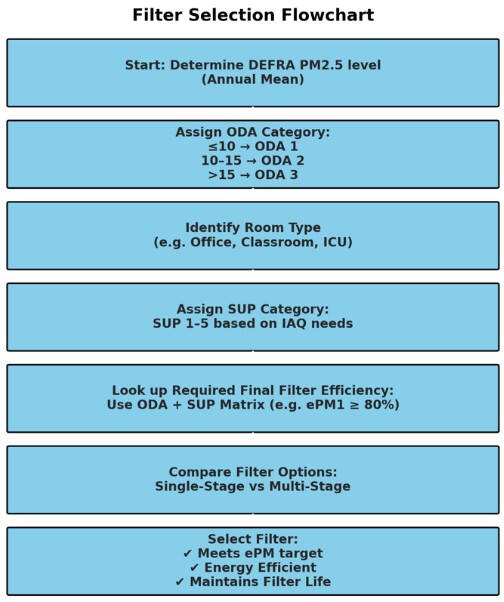

Figure 6: Filter selection flowchart

Step 5: Check Flowchart for Correct Procedure Guidance

To ensure the correct procedures have been followed, use this quick visual guide to verify that you have the appropriate filter configuration for your AHU. (As shown in Figure 6)

Final filter selection checklist

By the time you complete all the steps, a correctly selected filter should meet all the required parameters, as shown in Figure 7.

Figure 7: Final filter selection checklist

Conclusion: Achieving compliance with confidence

Selecting the right filters for your air handling unit (AHU) is not just a matter of operational performance—it directly impacts indoor air quality (IAQ), energy efficiency, and compliance with EN ISO 16890 and Part F of UK Building Regulations. By aligning ODA/SUP classifications with cumulative ePM1 filtration efficiency and referring to real-world pollution data from DEFRA, you ensure that your HVAC specification supports both regulatory requirements and long-term ventilation strategy goals. For sourcing high-quality replacement filters that meet these standards, visit AAH UK.

ECE UK supports building services professionals, consultants, and facilities managers with expert advice, practical tools, and robust technical documentation. From filter selection to full air handling unit maintenance, our services are designed to support best practices and lifecycle performance. If you’re unsure whether your installation meets current standards, request an air handling unit condition report or contact us to learn more about our management systems.

Explore our complete range of air handling units, filtration components, and support tools to ensure your building is operating at peak performance—with health, efficiency, and compliance built in.

Frequently asked questions

What is cumulative ePM1 efficiency, and why does it matter?

Cumulative ePM1 efficiency refers to the total filtration performance across all stages of your filter configuration. This metric is essential under EN ISO 16890 to ensure that fine dust particles and PM2.5 are effectively removed.

Do I need multi-stage filters for all building types?

Not necessarily. Your choice between single-stage and multi-stage filters depends on your ODA/SUP combination, application type, and target IAQ levels. A healthcare or education setting, for example, may require enhanced configurations.

How does air handling unit maintenance impact energy efficiency?

Regular air handling unit maintenance ensures filters are functioning correctly, reducing pressure drops and maintaining airflow efficiency—key factors in optimising HVAC system performance and reducing energy costs.

Where can I get a condition report for my existing system?

ECE UK provides expert air handling unit condition reports to assess current performance, identify risks, and recommend improvements based on EN ISO 16890 and BS EN 16798-3.

How do your management systems help with AHU compliance?

Our management systems support proactive maintenance scheduling, lifecycle tracking, and compliance documentation—ensuring every system meets regulatory and operational standards.

Contact our team today

Get straight through to one of our engineers and start discussing the needs of your new air handling unit. Our team are on hand to work out a custom solution for you and your project. Just call 01634 729 690 or send us an email at sales@eceuk.com to get started.