Wet Efficiency In RXA Thermal Wheels

For expertly carried out FATs, call 01634 729 690.

Wet Efficiency In RXA Thermal Wheels

In HVAC systems designed for environments requiring precise humidity control, various types of thermal wheels play a vital role, particularly the condensation, enthalpy, and sorption wheels featured in ECE UK Ltd’s RXA thermal wheel range. These advanced rotary heat exchangers not only enable efficient heat recovery but also support effective moisture transfer, significantly enhancing heat recovery ventilation and overall system performance.

Understanding the core principles behind these systems and how wet efficiency applies can help optimise functionality, support better indoor climate control, and improve air handling unit performance across commercial and industrial applications.

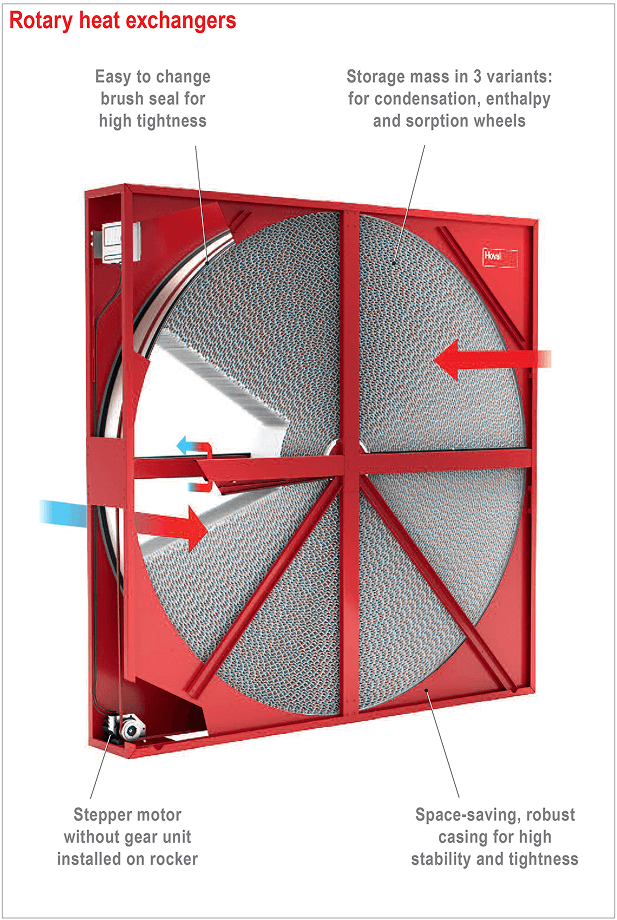

Below is a practical illustration of the Structure of Rotary Exchanger Aluminium (RXA), as shown in Figure 1. This detailed diagram of a rotary heat exchanger highlights its key components and features. It provides a clear, labelled view of how the unit functions as an energy recovery device, showcasing the design elements, such as the rotating storage mass, precision stepper motor, and high-tightness brush seal that contribute to its efficiency, flexibility and long-term performance.

Principle Of Operation: How The RXA Rotary Thermal Wheels Work

Rotary heat exchangers, also known as regenerative heat exchangers, play a central role in air handling unit (AHU) systems, particularly where heat recovery ventilation is essential. These systems operate through the continuous rotation of a rotor, allowing supply and exhaust air streams to pass alternately through the same medium.

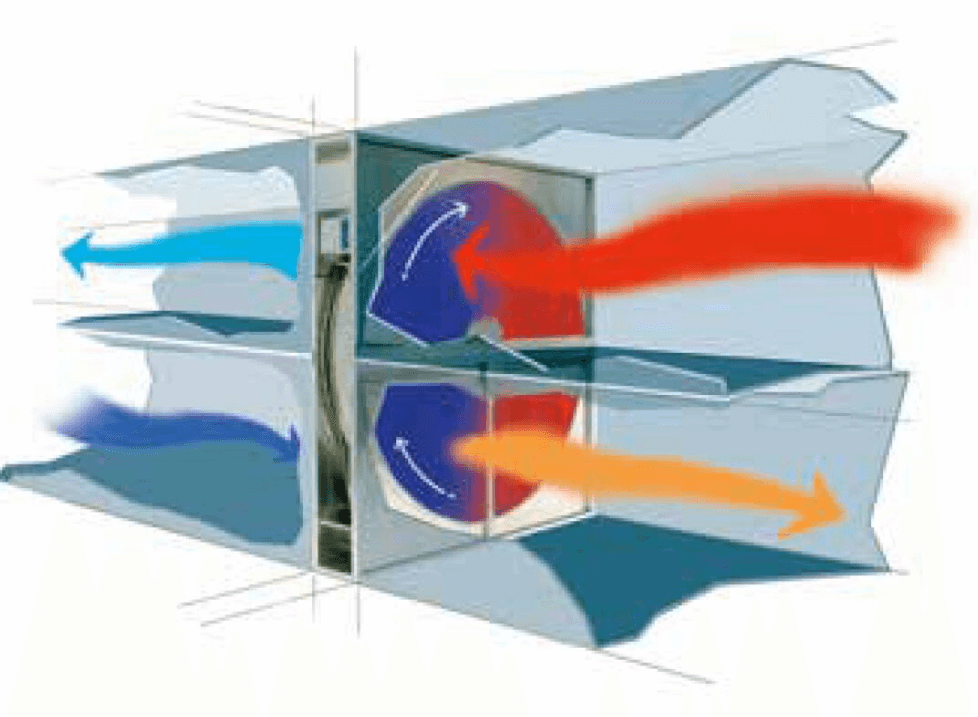

As the rotor spins, it absorbs heat and moisture from the exhaust air and transfers this energy to the incoming fresh air, significantly enhancing overall system efficiency. This process is illustrated in Figure 2, which shows the alternating airflow paths within the exchanger and how energy is effectively transferred between the two airstreams. This alternating airflow pattern also makes the system largely self-cleaning and frost-resistant.

Thanks to their ability to recover both sensible heat (temperature) and latent heat (moisture), rotary exchangers are known for their high performance. Typical thermal efficiencies range from 73% to 90%, with pressure drops maintained below 200 Pa, depending on the configuration. The heat recovery rate can also be adjusted by controlling the rotor’s motor speed (rpm), providing greater flexibility and energy optimisation across seasonal demands.

What Is Wet Efficiency In HVAC Systems?

In high-performance HVAC systems, particularly those using rotary heat exchangers, wet efficiency serves as a critical performance indicator. It evaluates how effectively a system can recover both sensible heat (temperature changes) and latent heat (changes in moisture content).

This dual focus is especially vital in applications with variable humidity loads, such as hotels, offices, and other commercial spaces. In such environments, maintaining indoor comfort goes beyond temperature control; humidity regulation plays a major role in occupant well-being, energy efficiency, and indoor air quality (IAQ).

Wet efficiency directly reflects a system’s ability to transfer moisture from exhaust to supply air, thereby reducing the need for additional dehumidification or humidification. Optimising this efficiency can lead to lower energy consumption and more stable internal climate control throughout the year.

Rotor Type And Their Role In Wet Efficiency

The performance of a rotary heat exchanger in managing moisture and heat transfer is strongly influenced by the type of rotor used. Each rotor variant has distinct construction characteristics and humidity transfer mechanisms suited to specific operational contexts.

As shown in Table 1, there are three primary rotor types used in RXA thermal wheels:

| Type of Rotor | Rotor Matrix | Humidity Transfer Principle |

|---|---|---|

| Condensation | Polished or epoxy-coated aluminium | Humidity transfer when condensation is present |

| Enthalpy | Surface with partially sorption coating (3Å molecular sieve) | Medium humidity transfer via adsorption and additional condensation if present |

| Sorption | Surface with sorption coating (3Å molecular sieve) | Large humidity transfer via adsorption |

Table 1: Construction and Humidity Overview of Rotor Types

Each of these rotor types offers a distinct balance of heat and moisture recovery, allowing for the tailoring of the system’s wet efficiency to meet seasonal demands, local humidity levels, and ventilation design objectives.

How Wet Efficiency Applies To

Thermal Wheel Technologies

In rotary heat exchangers, wet efficiency refers to the system’s ability to transfer both moisture (latent heat) and temperature (sensible heat) between airflows. This becomes particularly crucial in ventilation systems, where humidity control, energy savings, and thermal comfort are top priorities.

Rotary wheels (also known as thermal wheels) come in various configurations, depending on the application, each offering distinct levels of wet efficiency. Below, we explore three key types: sorption wheels, enthalpy wheels, and condensation wheels and how their material structure and design influence their performance.

-

Sorption Wheels

RXA sorption wheels are equipped with advanced materials that effectively adsorb moisture from the incoming airstream and release it into the outgoing airstream. Wet efficiency for these units evaluates how well they manage moisture transfer while recovering heat, maximising performance in environments where humidity control is critical.

The high-performance desiccant coatings of the sorption rotor (3å molecular sieve) provide maximum humidity transfer capacity with minimal carryover.

Sorption rotors offer an effective method of cooling and dehumidifying outside air before it reaches the air handling unit’s cooling coil. This leads to:

- Lower investment cost in cooling capacity (20–50% savings), allowing for smaller chillers and condensing units

- Lower energy consumption during cooling periods

- Better indoor air quality

- Increased humidity in winter

- Lower investment and operating costs for humidification

The RXA sorption wheels’ effectiveness in varying humidity conditions is highlighted through their moisture transfer capability, which directly impacts indoor humidity levels. They are ideally suited for ventilation systems with mechanical cooling.

As shown in Figure 3, a close-up of the rotor matrix (storage mass), the heart of the rotary heat exchanger. The image reveals a highly textured, corrugated surface made up of narrow passageways that maximise surface area for efficient heat and moisture exchange.

-

Enthalpy Wheels

RXA enthalpy wheels are partially coated with a sorption agent, enabling them to transfer moisture even during transitional periods when humidity levels fluctuate. This feature enhances wet efficiency by allowing the unit to manage both sensible and latent heat, making it highly effective during spring and autumn.

The hygroscopic surface of this rotor class supports humidity transfer and is typically used for standard applications in comfort ventilation systems to recover moisture during winter.

By optimising moisture transfer throughout the year, RXA enthalpy wheels contribute significantly to overall energy efficiency and indoor comfort.

They are ideally suited for commercial buildings, offices, hotels, and high-end residential spaces. The improved room climate is a result of the higher indoor air humidity maintained in colder periods.

Condensation Wheels

RXA condensation thermal wheels are designed to operate effectively during winter when moisture in the extract air condenses within the wheel’s storage mass. In this case, wet efficiency evaluates how well the wheel recovers latent heat from the moisture that condenses and then transfers it to the incoming fresh air.

These wheels act as a cost-efficient solution for recovering heat and are suitable for standard comfort ventilation applications. Humidity is only transferred when the dew point of one of the air streams is reached during winter.

This unique capability allows condensation wheels to enhance indoor humidity management in colder months, ensuring consistent comfort and well-regulated air conditions. They are ideally suited for commercial and office buildings, hotels, and high-end housing.

Below is an image (Figure 4) of a condensation-type thermal wheel installed inside a ventilation unit. The image highlights the semi-transparent rotor disc mounted within a metallic housing. The grooved surface and slow rotation help retain and transfer heat from condensation, enabling efficient moisture and temperature exchange.

System-Wide View: Evaluating Combined Sensible And Latent Heat Recovery

Now that we’ve explored how each RXA wheel type, sorption, enthalpy, and condensation contribute to heat and moisture transfer, it’s essential to step back and consider the overall efficiency of the system.

Wet efficiency provides a comprehensive performance indicator, enabling engineers to assess how effectively both sensible heat (temperature) and latent heat (moisture) are recovered across all rotor types. This combined view is crucial in real-world HVAC environments, where thermal loads fluctuate with changing seasons and occupancy levels.

By assessing both temperature and humidity recovery simultaneously, wet efficiency provides a more accurate reflection of system performance and potential energy savings across a wide range of applications, from commercial buildings to climate-sensitive facilities. It also ensures better alignment with indoor air quality standards and ventilation design goals, helping reduce overall energy consumption while maintaining consistent comfort.

Conclusion

When designing HVAC systems that incorporate RXA Sorption, Condensation, or Enthalpy wheels, wet efficiency should serve as a guiding factor for engineers looking to optimise moisture management without sacrificing heat recovery performance.

By prioritising wet efficiency during the specification and selection process, ECE UK Ltd ensures each thermal wheel delivers the right balance of sensible and latent heat recovery tailored to the system’s operational demands.

This dual-focus approach not only enhances energy savings and system efficiency but also contributes to improved indoor climate control, air quality, and overall occupant comfort throughout the year.

At ECE UK Ltd, our in-depth understanding of energy efficiency enables us to develop and implement HVAC solutions that excel in both temperature and humidity regulation, particularly in commercial environments where optimal cooling performance and precise humidity control are crucial to long-term success.

Contact our team today

Get straight through to one of our engineers and start discussing the needs of your new air handling unit. Our team are on hand to work out a custom solution for you and your project. Just call 01634 729 690 or send us an email at sales@eceuk.com to get started.